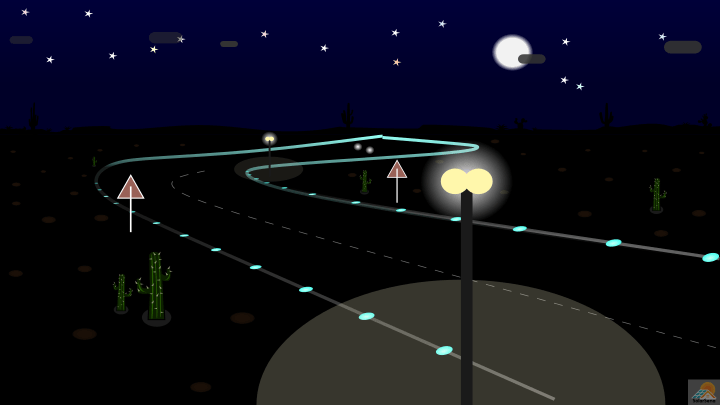

Road studs are a road marker that shines at night. Seen as small elevations on the road surface, they mark the boundaries of lanes and improve driving safety. A cat’s eye is a conventional road maker and commonly installed on roads around the world. However, with the advancement in solar technology, a new category of studs are getting into the market. And they are solar road studs.

Solar road studs absorb solar energy coming from the sun and produce light when it is dark. Although solar road studs feel better technology, the adoption of them seems slow. In the article, we will learn about these new studs and why they are a promising replacement.

What are solar road studs?

Solar road studs are blinking solar-powered devices affixed on roads. As an alternative to the cat’s eye, they are road safety signs and help to ameliorate the attention of a driver. They work as isolated units and are not dependent on the power grid. During the day, they absorb sunlight and emit the stored energy at night.

We use them to mark edges and centerlines of lanes.

In the video below, solar road studs are used to give direction on a one-way lighting road. When a vehicle moves in the right direction, the driver will see a green arrow. While in the wrong direction, a red cross is seen.

The video also indicates how creative these electronic devices can be.

Construction and working

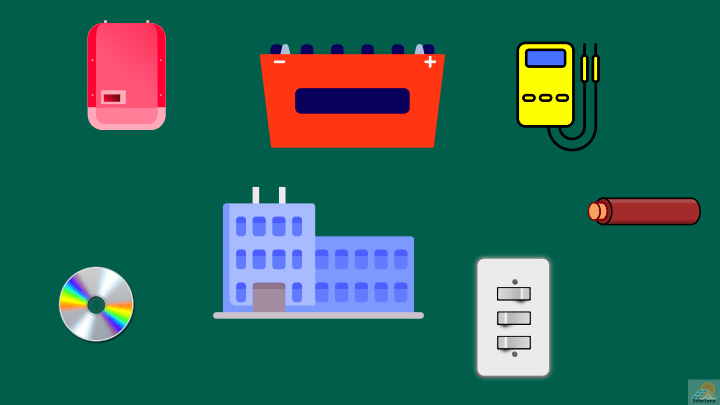

Solar road studs are simple electrical devices. They consist of a solar cell, LED lightings, a battery, a protective body, and a photoswitch.

The elements are discussed below:

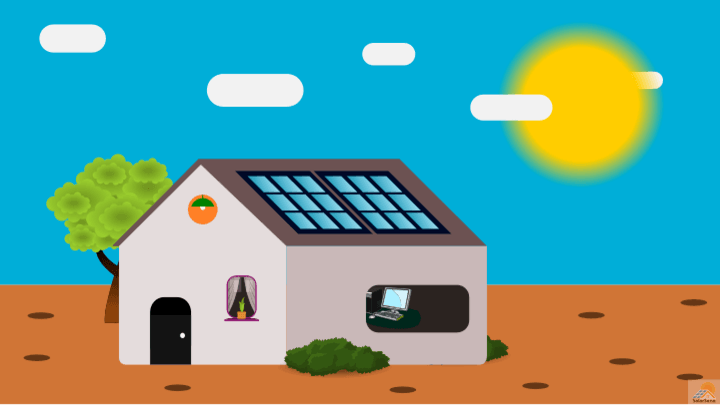

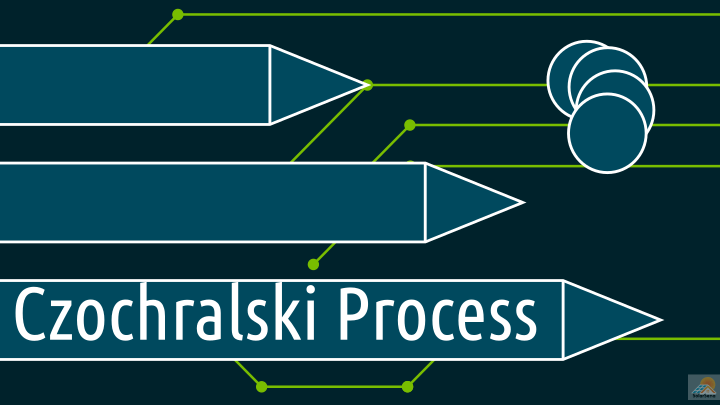

- Solar cell: It is a photovoltaic device, usually made of crystalline silicon, that converts incident solar energy into electrical energy. It has a dark bluish hue.

- LED: The light-emitting diode (LED) is a semiconductor device that operates the reverse of the solar cell. It converts electrical energy into solar. By using different junction materials, we can create LEDs of different colors. The common colors used in road transport are red, yellow, green, and blue.

- Battery or capacitor: A battery or capacitor stores the solar energy and supply energy when required.

- Body: The body of solar road studs protects the rest of the parts of the stud. The material of the body is commonly a metal or engineering polymer or polycarbonate. Since heavy vehicles will be marching on solar road studs in the field, the body must be able to withstand the load.

- Photoswitch: Photoswitch is photoelectric material that closes/opens the circuit in response to light stimuli. In the day, the photoswitch disconnects the current flowing through LEDs.

Typically, solar road studs have 100 mm of diameter and 55 mm of thickness. The exact dimension will vary from manufacturer-to-manufacturer.

The working of solar road studs must be clear from the above points. In the sun, the light falling on the solar cell is absorbed and converted into electric current. The produced electric current is stored in the battery or capacitor, which supplies current to LEDs at night. Photoswitch regulates the flow of current.

Solar road stud vs cat’s eye

The cat’s eye is a traditional road safety marker and is very common. It is a retroreflective device, which means it reflects light, not produces light. You can think of the cat’s eye as a mirror that reflects light in the reverse direction.

Let’s say you are driving a car. The light from the headlights of your car falls on the cat’s eyes on the road. The cat’s eyes reverse the direction of the incident light and reflect back to you. Thus, you apparently see them shine. And it falsely appears they are producing light.

Why are solar road studs better?

Cat’s eyes have an advantage of price. They are very cheap compared to solar road studs. Also, they are less complicated since there are no electrical parts, no LEDs, no battery, only reflectors. The lack of any electrical parts makes them maintenance-free devices.

However, these reflectors are light-dependent. If there is no light source, they will not work and fail to provide safety. This makes them useless in some cases.

Solar road studs overcome such problems since they themselves are the light source. Further, the light produced by LEDs is intense, bright. Even at hundreds of meters, solar road studs are effective. In heavy rain and fog, these devices perform far better than conventional cat’s eyes. Also, in snow, they are more effective.

A single-charged solar road stud can last for over 6 days. So, when the sun is low, especially in winters, the battery has enough power to light LEDs for many nights.

A common driving problem, which causes fatal accidents, is sudden dazzling due to an oncoming vehicle. It is because of the direct flashing of the light beam from the approaching vehicle into your eyes. It makes you temporarily blind.

Solar road studs can help to mitigate this issue as well. When road markers are self-illuminating, the need for bright headlights is optional and unnecessary.

In areas where traffic lights and street lights are out of reach, solar-powered markers are promising devices. That is true in remote and rural areas.

Unlike cat’s eyes, solar road studs require maintenance and replacement of parts after a few years since electrical parts, particularly batteries, have a limited life span.

Hybrid

We can have a hybrid of both. In fact, such a mix is way common—see the figure below.

The hybrid takes the advantages of both. Now, even if any electrical components fail, the device will continue to work to some extent because of reflectors.

Types of solar road studs

Based on the structure of the body, we can have three varieties of solar road studs. The first is classical studs, shown in the above diagrams. When installed, they give a small elevation on roads. Screws are used to fix this type on the surface of a path.

The second variety is the studs with a center shaft—see diagram below. A wide central shaft that penetrates the road improves the installation with the ground. Similar to the first, it remains above the surface, giving an elevation.

Embedded solar studs are the third type. They are quite different in appearance from the above two, but the working principle is the same.

The installation of this type involves drilling a cylindrical hole on the path. After removing debris, glue is poured into the hole. Finally, the stud is pressed in the hole and allowed to set.

Spacing

The spacing between each stud depends on the lane. For example, in dangerous lanes, studs are closely packed compared to highways. It better catches the attention of drivers and consequently improves safety. The common spacing guidelines are given in the following table.

| Roadways | Vehicle speed | Spacing (meter) |

|---|---|---|

| Highways | High | 5 to 6 |

| Risk lanes | Medium | 2 to 3 |

| Parking lots | Low | 0.5 to 2 |

Applications

Being robust and water restraint, solar road studs are suitable to use in various pavements. It covers highways, expressways, dangerous entrances & exits, parking lots, petrol stations, commercial lanes, taxiways at airports, marine applications, etc.