Monocrystalline and polycrystalline are two popular types of silicon solar panels in the solar market. They both serve the same function, i.e., convert solar energy into electric energy. However, just because they work in the same way does not make them the same. There are many differences between them. And selecting which is better and right for you might not be so straightforward. This article helps readers to get the distinction between monocrystalline and polycrystalline solar panels.

A quick comparison between monocrystalline and polycrystalline solar panels

Monocrystalline and polycrystalline solar panels differ from one another in many aspects. It includes material, cost, efficiency, performance, and appearance. Each of the types has its own advantages and disadvantages. You can not blindly say one is superior to another. The right selection will depend on the specifics of your needs.

Here is a quick comparison of the two.

| Property | Monocrystalline solar panel | Polycrystalline solar panel |

|---|---|---|

| Material | Monocrystalline silicon | Polycrystalline silicon |

| Cost | High | Low |

| Efficiency | Above 20% (More efficient) | Below 20% (Less efficient) |

| Performance | Good | Not bad |

| Color | Bluish | Blackish |

| Aesthetics | Dull | Appealing |

| Lifespan | 25+ years | 25+ years |

| Nature | Rigid | Rigid |

Similarities and differences between monocrystalline and polycrystalline

Before heading to the differences, it would be better if we understand the similarities between the two.

Solar panels are the assembly of different components: solar cells, a frontend glass coating, a backend polymer sheet, and an aluminum frame.

Both monocrystalline and polycrystalline have the same glass coating, backend sheet, and aluminum frame. The only difference between the two is different solar cells. Yes, it is all the solar cells that separate the two. The rest A to Z is no different.

Monocrystalline panels, as the name says, are made up of monocrystalline solar cells, and polycrystalline panels are made up of polycrystalline solar cells. These solar cells are several square units that are composed of thin layers of crystalline silicon. When light falls on them, they absorb and convert it into electricity.

It is these solar cells that drive all the differences in the properties and performance of the solar panels. In the following sections, we will be looking at the distinguishing characteristics of the two.

Material

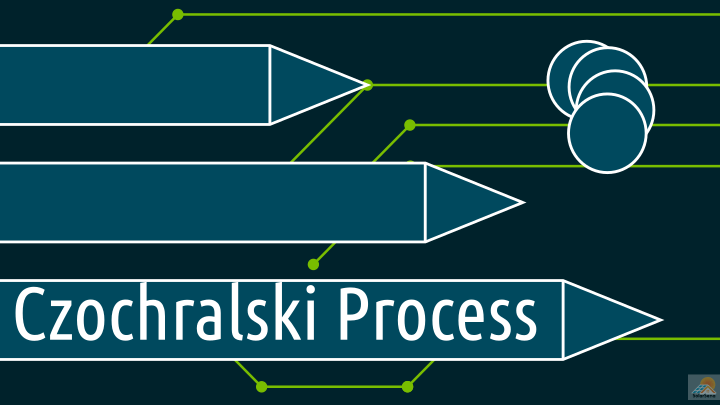

Monocrystalline solar cells are made of monocrystalline silicon, while polycrystalline cells are produced from polycrystalline silicon.

Monocrystalline silicon is a superior material since its crystal structure is uniform and organized. On the other hand, crystals in polycrystalline silicon have no specific orientation; they are randomly organized. In more technical words, monocrystalline silicon is free from grain boundaries, while polycrystalline has disoriented grain boundaries.

The former is a single-piece material. There are no internal breaks and boundaries in monocrystalline material. That’s why it is called mono (single) + crystalline (crystal). The entire material represents one single-piece crystal. On the opposite side, the latter has internal breaks and boundaries. Polycrystalline is composed of many small crystals that are clumped together.

You could think of monocrystalline as a single-piece transparent ice cube and polycrystalline as clumped flake ice.

Cost

The cost of monocrystalline silicon solar panels has always been higher than polycrystalline. That is because of the higher production cost of monocrystalline silicon. In fact, monocrystalline silicon itself is produced from polycrystalline silicon, so naturally, the former will always be more expensive than the latter.

Efficiency

As mentioned earlier, monocrystalline silicon is a superior material. Unlike in polycrystalline, its thermal, crystal, and electrical properties remain the same throughout the material. The electrical charge carriers receive minimum internal resistance as they transport the energy. Consequently, the efficiency of monocrystalline is higher than polycrystalline.

The brand-new monocrystalline solar panels will give an efficiency above 20%, whereas polycrystalline panels will deliver less than 20% efficiency.

The typical efficiency values for monocrystalline panels are between 18 to 22%, while the values are between 15 to 18% for polycrystalline panels.

From the above graph, we see that the efficiency of monocrystalline has always been higher than polycrystalline.

Both types of panels suffer from deterioration after a few years of use. However, mono will still be more efficient than poly.

Polycrystalline panels are cost-effective, compared to Monocrystalline. However, they have lower efficiency as compared to the latter.

Performance

For the same size of panels, monocrystalline performs better than polycrystalline. Because of the high efficiency of monocrystalline panels, they produce more power; and more power means we have more wattage.

Another factor that might affect the performance is the temperature coefficient. As the temperature of the surroundings increases, the energy loss also increases. As a result, the panels deliver less power. Monocrystalline panels are more resistant to higher temperatures, but this is no standard rule. Most of the time, we can ignore the impact of higher temperatures on solar panels’ performance when choosing between polycrystalline and monocrystalline.

Appearance

Appearance is a personal factor. Some people find polycrystalline solar panels unattractive and ugly. That because of its bright bluish hue. Further, we can see irregular lines and wrinkles on the polycrystalline solar cells. All this spoils the appearance of polycrystalline.

In the case of monocrystalline silicon, its homogeneity reflects in its look. Its panels display a black glossy hue. There are no wrinkles or lines. Because of aesthetics, monocrystalline panels feel like premium products and appeal more to customers.

Another notable distinctive feature between the two is the clipped corners of monocrystalline solar cells. During the processing, the corners get clipped, which gives them an octagonal shape.

Longevity

Both types have long life spans. Many manufacturers in the market give 25+ years warranty for their crystalline silicon solar panels.

Nature

Both polycrystalline and monocrystalline panels are rigid. They are not available in flexible or semi-flexible forms, like thin-film panels. The reason behind the rigidity is the greater thickness of crystalline solar cells. If we apply deformative force on these cells, they will break rather than bending.

Market share of monocrystalline vs polycrystalline

A way good to judge monocrystalline and polycrystalline solar panels is by looking at their market demands.

As we can see in the above figure, monocrystalline silicon was in demand in the 1980s compared to polycrystalline; but its market quickly fell soon after and continued to decline until 2015. However, in the last few years, we saw a spike in its demand. In 2019, monocrystalline silicon accounted for 65.6% of the global PV market, whereas polycrystalline decreased to 28.9%.

One of the reasons why there is a surge in monocrystalline is its modules are more appealing to consumers and are more efficient, and manufacturers further promote monocrystalline.

Which solar panel is better, and which is right for you?

As we look above, each type has some advantages and disadvantages. We can use both panels for most purposes. But selecting the right one might sometimes be confusing, so below are some points that will help in deciding what is better and when.

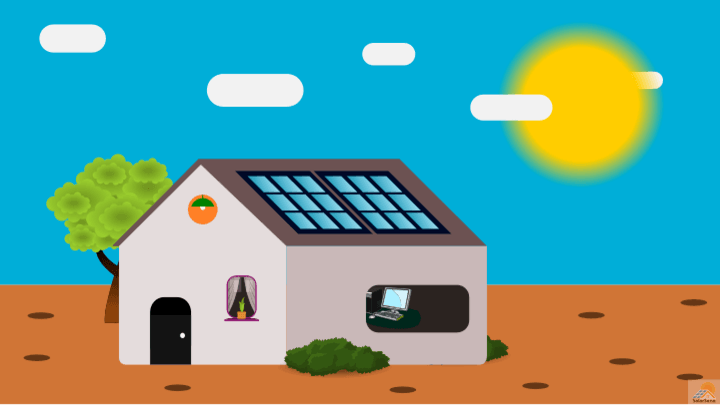

Polycrystalline solar panels are cheaper but less efficient. Their less efficiency does not mean that they are not a good option. In fact, many times, polycrystalline is a wiser choice. Besides being more affordable, polycrystalline, on decent sunny days, provides significant solar power. We can overcome the low efficiency by installing more panels; however, more panels might increase the cost of other components of photovoltaic systems. Of course, more panels will require more open space. So, if your property has enough open roof space or ground space, polycrystalline panels will be a better and cost-effective option.

Monocrystalline solar panels perform better than polycrystalline. They are also more efficient, however expensive. Having more efficiency implies they will generate more power than the same size polycrystalline. This becomes important when open space is limited, and we want to generate higher solar power from that same limited space. Such a situation occurs when your roof is not enough, or the orientation roof is in the wrong direction. Sometimes, people want to go 100% solar. In such circumstances, monocrystalline panels become a more viable option.

Another reason people want monocrystalline is to save the aesthetics of their homes or premises. Monocrystalline panels have a polish and modern appearance and will add value to the sight of owners’ property.

In the US, people love camping and often move out with their RVs. So, for RVs and other vehicles like boats, monocrystalline panels will be the recommended choice since there is limited open space, and we want more power from that. But polycrystalline panels can also be mounted on portable PV systems; they also work well.

Note to consider, RVs, boats, and other vehicles have curved surfaces. You will require a mounting structure to fix rigid crystalline silicon solar panels. Or you can opt for thin-film solar panels, which are flexible and can be fixed on curved surfaces of RVs and boats.

One more point to consider is monocrystalline panels are thought of as premium products. Consequently, some companies will possibly overprice the panels. It is always better to do some self-research to escape from such traps.